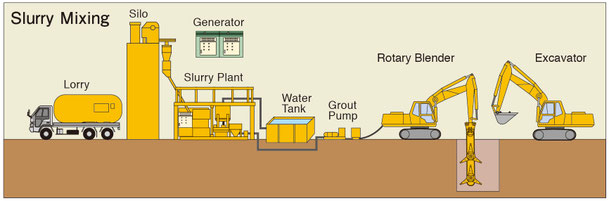

Shallow Soil Mixing (SCM)

Rotary Blender and Bucket Mixing

SCM (Surface Compact Mixing) is one variety of Mechanical Soil Mixing technology. As the name indicates, it improves the soft ground shallowly. The compact mixing equipment, attached to a standard 0.7m3 to 1.0 m3 excavator, can improve the soft ground to the depth of up to 7 m. This technique is applied to improve the foundation soil and prevent settlement of road, embankment, and building as well as to solidify and stabilize the contaminated soil.

Applicable to Various Site Conditions

SCM is a method to mechanically mix in-situ soil with cement powder or slurry. SCM provides two different mixing equipment, Rotary Blender and Bucket Mixing, to be selected depending on improvement objectives and depth. The unique mixing mechanism provides efficient, cost effective and quality improvement. Larger plant is not necessary.

The mixing device can be attached to a local 0.8-1.9 square meter excavator.

Operation System

Rotary Blender Type

Bucket Mixing Type

Alternative Technologies

Multi-auger DSM

DSM is an in-situ soil mixing technology that mixes existing soil with cementitious materials using mixing shafts consisting of auger cutting heads, discontinuous auger flights, and mixing paddles. The mixing equipment varies from single to eight shaft configurations depending on the purpose of the deep mixing.

Soil Mixing Wall

RSW mixes in-situ soils with cement grout or other reagents slurries using a multiple shaft auger to produce continuous subsurface soil-cement walls for excavation support, groundwater or underground pollutants control, or ground reinforcement. The soil-cement is usually reinforced with steel H-piles when used for excavation support along with groundwater control.

Large-diameter

RAS Column is an advanced deep soil mixing method based on mechanical soil mixing technology to produce soil-cement column of 1.4m to 2.5m diameter. The mixing head is equipped with the counter rotation mechanism. This unique mechanism efficiently breaks and mixes in-situ soil with cement-based reagents, producing more homogenous and higher quality soil-cement columns.