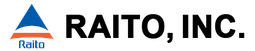

Fremont Grade Separation Project

This grade separation project at that time was the largest project yet undertaken by the City of Fremont. Work included an overpass on Washington Boulevard, an underpass on Paseo Padre Parkway between Shadow Brook Common Road and Hancock Drive to separate car and pedestrian traffic from the rail road crossing.

Also, 1.5 miles of the rail was relocated 500 ft. to the east in the area between Paseo Padre Parkway and Washington Boulevard. An overpass for the planned BART extension from the downtown Fremont to Warm Springs Station will be built over Paseo Padre Parkway.

The retaining wall portion of the work was design-build. Raito performed this portion of the work including beams and tie-backs. Soil types in the improved zones included loose sand and high plasticity clan.

DSM walls were installed for temporary excavation support until a concrete structure for the road-way under-crossing was built. DSM also provides permanent seepage control of subsurface water to help reduce lateral inflow.

In addition, DSM walls were used to maintain stability for abutments of the bridge supporting the Union Pacific railroad. The bridge abutments were 22 ft. behind the retaining walls. These walls were designed with lateral earth pressure and train surcharge from Cooper E80 loading.

A test section was performed prior to full production to verify that installation procedures and mix designs would provide sufficient strength, uniformity and permeability to meet the design intent.

DSM production was performed in two stages, East and West. All retaining/cutoff walls were installed to EL. 10 ft. Vertical beams were inserted at 4 ft. on center in wet soil cement with bottom EL. 13 ft. to 36 ft. depending on retaining wall height. Tie-backs were installed for the area of the deepest excavation, adjacent to traffic 22.5 ft. deep from the ground surface.

Actual mean strength of cored DSM was 100 psi at 28 days which exceeded the required 60 psi. Core recovery was 80%. Maximum permeability of wet sample testing was 5x10-7 cm/sec at 28 days, which exceeded specification requirements.

Soil-cement excavation support /

groundwater cutoff

6-Axel DSM Rig

Completed project - North bound

Completed project - South bound

Project Highlights

- Deep Soil Mixing (DSM) was used for temporary excavation support and permanent ground water control.

- Six-axel DSM equipment was used to a depth of 54 ft. One DSM soil mixing rig was used with a single shift.

- Acceptance criteria required average unconfined compressive strength of 60 psi at 28 days.

- Hydraulic conductivity required a maximum permeability of 1x10-6cm/sec at 90 days.