San Pablo Dam Upgrades

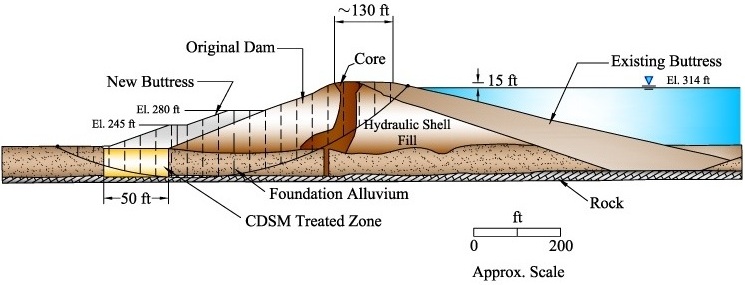

The earth-fill San Pablo Dam was built in 1920, creating a drinking water reservoir and recreation area northeast of Berkeley, California. The owner is the East Bay Municipal Utility District (EBMUD) and the reservoir capacity is 38,600 acre-feet. Fill for the dam foundation was hydraulically placed, which can result in poor performance during seismic shaking. After a seismic study determined that the dam foundation was vulnerable to liquefaction from earthquakes on the Hayward Fault Zone, the water was lowered to a safe level in 2004.

Based on the seismic study and review by EBMUD and the state Division of Safety of Dams (DSOD), alternative soulutions were evaluated. Deep Soil Mixing (DSM) was chosen to mitigate liquefaction in the downstream toe of the dam foundation. This application of the DSM process involves strengthening the soil in place by mixing cement grout with existing soil to form grids of walls in the ground. These grids limit shear strains in the soil during earthquakes to mitigate liquefaction.

DSM allowed the reservoir to remain in use during construction with a minimum of impacts to the environment. The existing stability berm and downstream toe of the dam were graded to provide work pads for DSM. Since holes are not drilled, soil stockpiles are minimized on the small site. DSM also minimized the need to borrow fill for the added stability berm placed on top of the DSM zones. Fill came from the adjacent hills, avoiding off-site import.

Project Highlights

- Improve the embankment and foundation soils downstream of San Pablo Dam to withstand the shaking generated by the maximum credible earthquake on the Hayward Fault Zone, prevent release of reservoir water, and protect public safety.

- Triple-axle DSM equipment was used to improve soils to a depth of 80 ft on average. Two DSM rigs and pre-drilling rigs, working double shifts, were used on the project site.

- DSM construction exceeded unconfined compressive strength and soil mix uniformity design requirements. Design specifications for unconfined compressive strength of shear walls varied with the spacing of DSM walls.

- This project won the ASCE Region 9 Outstanding Geotechnical Project of the Year 2009 Award.