Excavation Support Wall

Raito has tremendous experience in excavation support systems including permanent and temporary excavation support walls, and has constructed numerous projects for buildings, transportation facilities, and other civil works projects. Excavation support systems are used to minimize the excavation area, to keep the sides of deep excavations stable, and to ensure that movements will not cause damage to neighboring structures or to utilities in the surrounding ground.

We offer Soil Mixing Wall (RSW) for excavation support wall. RSW uses multiple auger, paddle shafts rotating in alternating directions to mix in-situ soil with cement grout, bentonite slurry, clay slurry, or other stabilizing reagent slurries to install continuous subsurface soil-cement walls for excavation support and groundwater or underground pollutants control, or ground reinforcement; column blocks, lattice, or areal patterns for stabilization. Excavation support systems are temporary earth retaining structures that allow the sides of excavation to be cut vertical or near vertical. This is done to maximize the size of an excavation; when the price of real estate is high or space is limited by property lines, utilities or existing structures.

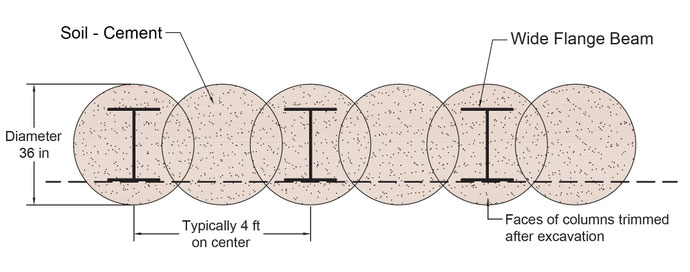

RSW walls constructed with wide steel reinforcement (usually wide flange H-beams or sheet piles) and other reinforcement supports such as tiebacks are very stiff and offer a cost-effective alternative to slurry walls and secant pile walls. Steel H-pile or other reinforcement members are installed inside the soil-cement wall to resist the lateral forces. The reinforce soil mix wall becomes a structural wall for excavation support and groundwater control.

The typical arrangement of excavation support walls is illustrated below. Steel reinforcement is installed in every other RSW column before the soil-cement hardens and the accessible face of each column is trimmed off once the excavation is complete. The wall system is supported with at least one level of struts or anchors and walers for horizontal support. It is common for RSW excavation systems to have multiple levels of support. The reinforce soil mix wall becomes a structural wall for excavation support and groundwater control.

Our Technologies

Soil Mixing Wall

RSW method mixes in-situ soils with cement grout or other reagents slurries using a multiple shaft auger to produce continuous subsurface soil-cement walls for excavation support, groundwater or underground pollutants control, or ground reinforcement. The soil-cement is usually reinforced with steel H-piles when used for excavation support along with groundwater control.

Jet Grouting

Jet Grouting is a technique of mixing in-situ soil with the energy of ultra-high pressure jet of slurry. A small-diameter rod drills down to the improvement bottom. Then the rod, while being withdrawn, jets the cement-base slurry and air to produce an improved column. Jet Grouting enables improvement closely contacted to or, in some cases, encompassing existing underground structures without causing damage to them.

Solutions

Public Safety Building

A major component of the City and County of San Francisco’s Justice Facilities is a new Public Safety Building. The state-of-the-art building houses the San Francisco Police Department Police Command Center, the Southern District Police Station and a neighborhood San Francisco Fire Department Fire Station. RSW was installed for excavation support wall of the basement.