Jet Grouting

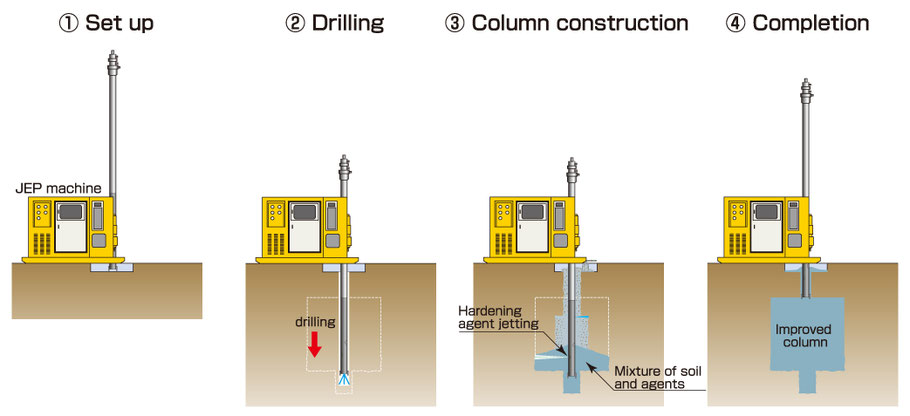

Jet Grouting is a technique of mixing in-situ soil with the energy of high-pressure jet of slurry. A small-diameter rod drills down to the improvement bottom. Then the rod, while being withdrawn, jets the cement-base slurry and air to produce an improved column. The compressed air and hardening agents which usually consists of cement and water are jetted with a high-pressure energy and discharge rate from jet monitors in horizontal direction to construct larger diameter soil-cement columns.

Jet Grouting enables improvement closely contacted to or, in some cases, encompassing existing underground structures such as buried steel pipe or concrete structure without causing damage to them.

Our sophisticated Jet Grout technology creates the energy of ultra-high pressure jet slurry which cuts in-situ soil very small pieces while jet rotates and cross in the ground to form the high quality large soil-cement column.

Works for various site requirements

Raito has been developing a wide variety of Jet Grouting method over the decades such as JEP, CCP, OPT-Jet, Mega-Jet, JSG, CJG, RJP etc. and the unique technologies are adaptable various site requirements with the high quality product, high speed, low-desludging cost effective construction. The large diameter improvement is maximum of 17 feet in diameter depending on the soil condition and specification.

JEP system

Large diameter Jet grout Column

(1) Large Diameter Column

Hardening agents are jetted with a high energy and discharge rate from double jet monitors to construct larger diameter improved columns (dia 3.5 m)

(2) High Speed Construction

Double jet makes the process more efficient as compared to conventional jet grouting and shortens construction term.

(3) High Quality Product

In-situ soil is cut into smaller pieces while two jets rotates and crosses in the ground.

(4) Cost Effective

The large diameter improvement reduces the number of columns required.

Construction Sequence

|

|

| Cutting Materials | Standard Discharge Capacity | ||

|

Ultra-high pressure Jet (upper monitor) |

Water | Pressure | 40 MPa |

| Discharge Rate | 50 L/min | ||

|

Ultra-high pressure Jet (lower monitor) |

Harding agents | Pressure | 35 MPa or more |

| Discharge Rate | 300 L/min | ||

| Compressed Air | Pressure | 1.05 MPa | |

| Discharge Rate | 4 to 8 m3/min | ||

Plant Configuration

Applications

Raito’s Jet Grouting may be used for the widest range of soil types of all kind of soil ranging from clay to silts and gravels, also for non homogeneous soil formations and changing soil layers, including organic material. Raito's the most advanced Jet Grounting technology ensures to create high-quality products in any situation requiring control of groundwater or excavation of unstable soil. Jet grouting’s ability to construct around subsurface obstructions such as utilities, provides a unique degree of design flexibility.